What is the TTR (Tri Thermal Roofing) System?

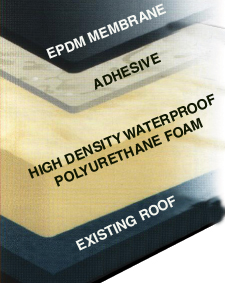

The TTR Tri Thermal Roofing system is a unique combination of two separate roof systems that combine to form the best roofing system available. The system is comprised of a spray applied Polyurethane Foam Roof with a single ply membrane that is adhered to the Polyurethane foam with a proprietary spray applied slow rise urethane based adhesive. While others have tried and failed at creating similar systems, our patent protected system succeeds!

You already know that the Polyurethane foam is the best insulation in the market. It covers the roof like a blanket in one seamless piece with no joints or gaps, this leads to reduced energy costs on average 25% savings.

The spray applied Polyurethane Roofing Foam Insulation used in the TTR System, not only has the highest R-value, it is waterproof. If your AC or mechanical contractor accidentally punctures your roof membrane, our foam roof will prevent water from infiltrating your building.

With other systems, once the membrane is punctured nothing stops the water from entering the building. The insulation boards used under the membrane are not waterproof and typically retain the moisture long after a rain event. This leads to prolong periods of moisture in roof system which expedites rust and substrate deterioration. The insulation boards used in other systems are only butted together which allows air leakage out of the roof, therefore decreasing the effective R-value of the roof.

The EPDM membrane used in our system can be either black or white in color. The membrane is available in a variety of thickness to suit your individuals needs. The Eco White membrane is available in 60 or 90 gauge thickness. White is the new green product with high reflectivity keeping the roofs cooler. Eco White membrane meets the Energy Star ratings and the Cool Roof Rating Council programs.

How does the TTR (Tri Thermal Roofing) System compare?

The TTR™ Tri Thermal Roofing system’s unique combination make this roof system the best roof on the market by building on all of the advantages and eliminating the negatives of the two separate roof systems that combine to form the TTR system.

TTR’s Spray Foam Roof Component:

- Is light weight, reducing cost by not having to tear off old roof. Making this system environmentally friendly.

- Is self adhering, and self flashing.

- It’s seamless & monolithic nature make it a superior insulation that is also waterproof.

- No heat or open flame needed during installation.

- 1in of foam can stop 70 % of heat loss

- 2in of foam can stop over 90% of heat loss

- 3in of foam stops 98 % of heat loss

TTR’s EPDM Single Ply Membrane Component:

- No coating is needed over foam roof. No recoats, ever !!

- TTR’s patented system uses no fasteners. No fasteners no reason to leak.

- Its fully adhered and no need for ballast , keeping the system lightweight.

- Black membrane is great for cold climates, white membrane is great for warm climates.

- The membrane is very easy to repair.

Comparison

Tar & Gravel (Built up Roof – BUR)

Advantages:

- System is inexpensive – can install 2 or 4 ply

- Rock coat makes it very durable

- Many plys for water to go thru and great puncture resistance

Disadvantages:

- Needs a hot open kettle or flame torch to install the system. The installation process produces strong orders and is not very environment friendly.

- Once felts are exposed it breaks down quickly.

- Cheaper bitumen and felts being used leading to poor quality roofs.

- Workmanship not once what it was.

Modified Bitumen Roofs

Advantages:

- System is comprised of multiple plies which can lead to thicker and stronger roof systems.

- Good puncture resistance

- Up to 50 year warranty

Disadvantages:

- Small rolls- 3 feet wide- more seams

- Needs a hot open kettle or flame torch to install the system.

- Costs dependent on price of crude oil, cost are becoming increasly expensive.

- Workmanship must be good

Single Ply Membrane Roofs

Advantages:

- Membranes are white for highly reflective energy star ratings

- Membranes are highly durable and easily repairable

- Larger width rolls and different gauges offer various installation options.

- Can be installed inexpensively on big box stores and new construction projects.

- Can be installed with mechanical attachment or fully adhered.

Disadvantages:

- Depending on thickness can be punctured easier than modified bitumen or tar & gravel.

- Regardless of mechanical or fully adhered installations, fasteners are still used for insulation attachment allowing thermal bridging.

- The system has many seams that need to be properly heat welded.

- Insulation boards are butted together allowing heat and cool loss and reduce effective R values.

Coatings

Advantages:

- Create a seamless barrier over roof and are highly reflective.

- Usually have foam under coating.

- Coatings are inexpensive fixes when not putting in complete insulation systems.

- Adaptable for many different roof configurations.

- No fasteners

Disadvantages:

- Some coatings are not very UV stable, the more stable & durable the more expensive.

- Multiple coats needed to provide a reliable system.

- Wind scouring of coatings is increasing – shortening life cycle of coating.

- Coatings are not very puncture resistant .

- Expensive primers are usually required for installation and systems need periodic recoating.

- Application procedure and installation very important; no ponding water conditions are not acceptable.

- Correct and constant millage is very difficult to install.

- Must be applied in certain conditions at certain temps, pressure and ratio.

Inverted Roofs

Advantages:

- Membrane is not exposed to elements.

- Easy to install.

- Cheaper to install as it is ballasted.

Disadvantages:

- If roof leaks it is very hard to find.

- Insulation eventually soaks up water and is no longer effective.

- Insulation becomes exposed and suffers UV degradation.

- Larger weight load on building.